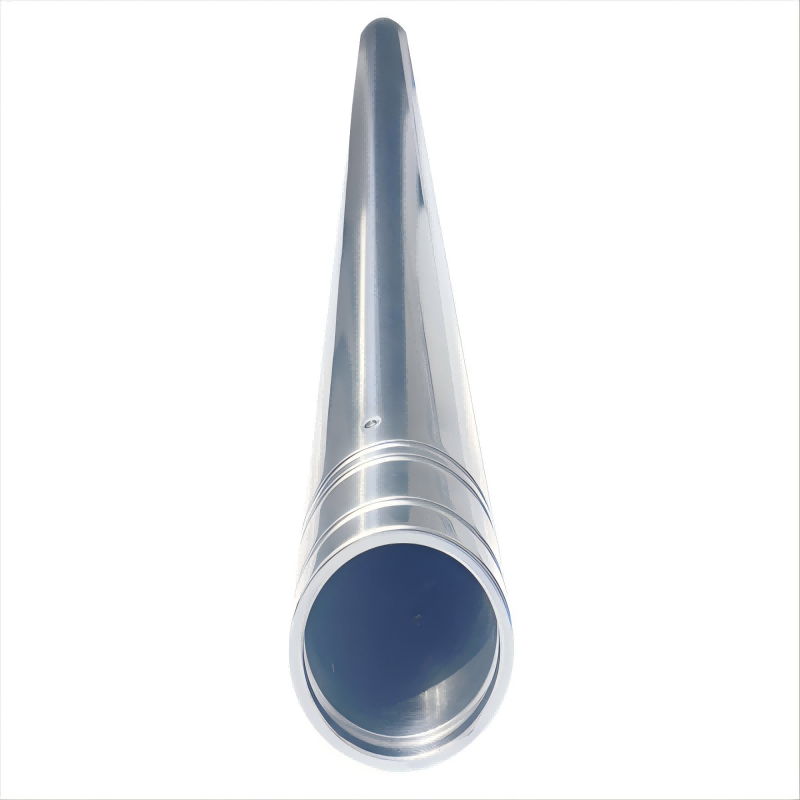

The welded inclined piston rod is a crucial component in hydraulic and pneumatic systems, designed for applications requiring an angled force. Its robust construction allows it to withstand high stress and deliver accurate movement, making it essential in industries demanding reliable and durable machinery. Engineered for superior performance and longevity, the welded inclined piston rod is indispensable in diverse industrial applications.

Product Overview

Welded inclined piston rods are built to function in systems that necessitate specific angled movements and force. These rods are made from high-strength materials such as alloy steel or stainless steel, chosen for their exceptional resistance to wear, corrosion, and high-pressure environments. The manufacturing process involves advanced welding and machining techniques to ensure the rods meet stringent quality standards and perform reliably in demanding conditions.

Key features of a welded inclined piston rod include:

These features ensure that the welded inclined piston rod is robust and reliable, making it suitable for challenging industrial environments.

Product Benefits and Advantages

The welded inclined piston rod offers several key benefits, making it vital in various industrial applications:

Product Application

Welded inclined piston rods are versatile and used in numerous industrial applications that require precise motion control and high stress tolerance. Common applications include:

Product Unique Selling Point

The unique selling point of the welded inclined piston rod lies in its combination of an inclined design, precision welding, and high-quality materials. This design allows for specific applications requiring angled force and movement, making it highly specialized. The advanced welding techniques ensure strong joints capable of withstanding high stress, enhancing reliability and performance.

Additionally, the use of premium materials and surface treatments ensures these rods can endure harsh conditions and maintain consistent performance. The ability to customize these rods further enhances their appeal, offering flexible solutions for various industrial challenges.

Product Customization

Customization is a significant feature of the welded inclined piston rod, enabling manufacturers to tailor the product to specific needs. Customization options include:

Offering extensive customization options, welded inclined piston rods can be precisely engineered to address unique industrial challenges. This flexibility, combined with their inherent strength and precision, makes them invaluable components in hydraulic and pneumatic systems where inclined force and motion are necessary.