Products

-

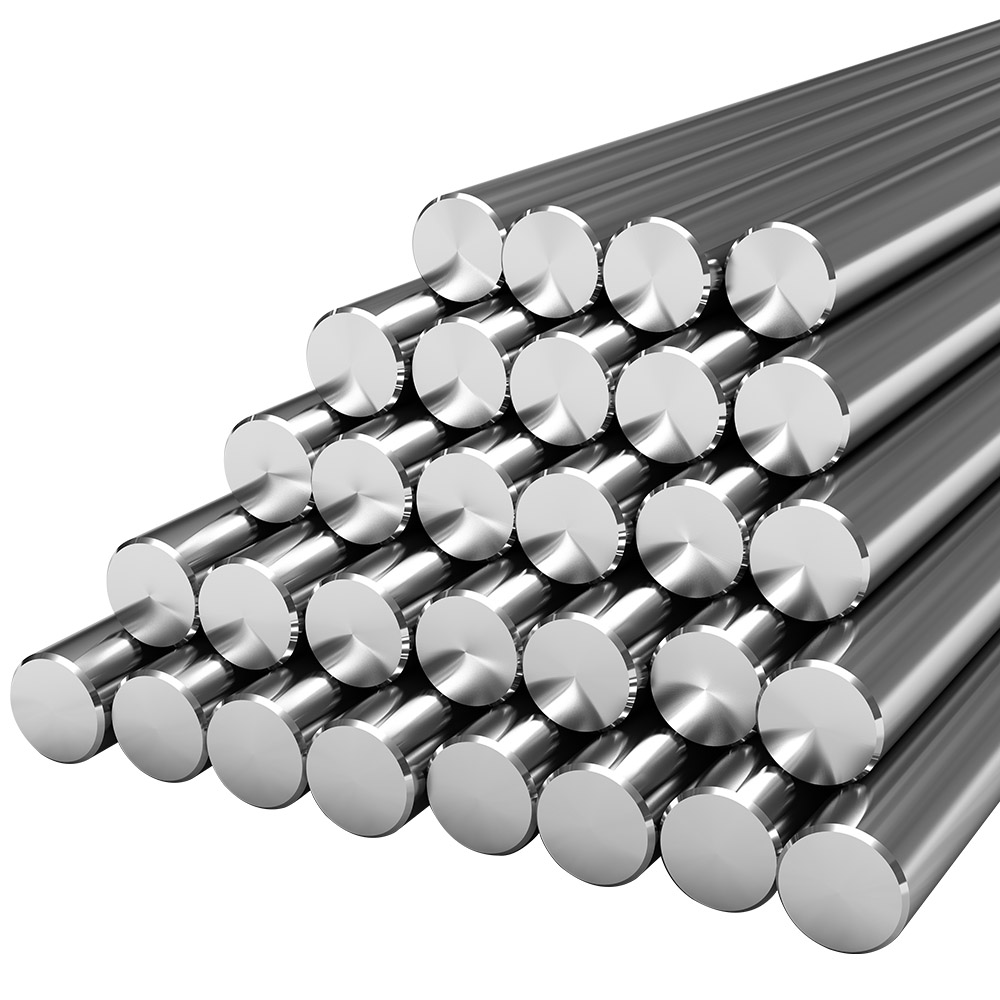

Hydraulic piston rod, 50-10000mm length, customizable, used in hydraulic cylinders, forklifts, lifts, etc

-

Pitch Piston Rod for Forklift Outer Diameter 4-500mm

-

Injection Molding Machine Guide Shaft Length 500-7500mm

-

Crane Leg Piston Rod Outer Diameter 4-500mm

-

Forklift Tilting Piston Rod

-

Electroplated Rod Length 500-7500mm

-

Forklift Tilting Piston Rod Outer Diameter 4-500mm

-

Customized 3T Forklift Steering Piston Rod

-

Hydraulic rod

-

Automobile hollow rod shaft, diameter 20-500mm, customizable

-

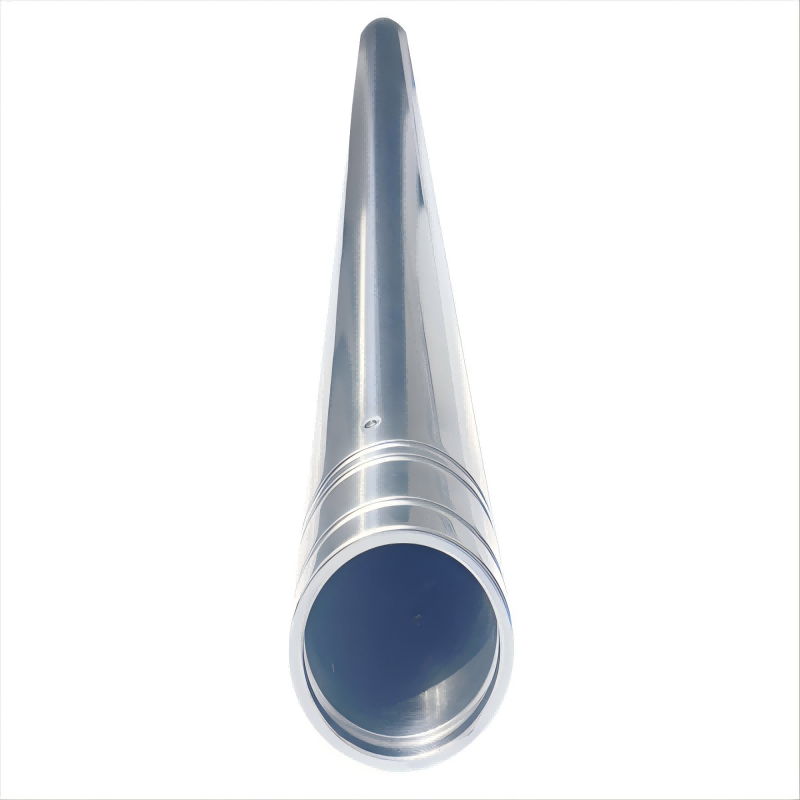

Hollow smooth rod can be customized 50-500mm

-

Threaded hollow shaft,CK45 material, customizable diameter 50-500mm

-

3T forklift steering piston rod Length 500-7500mm

-

Crane Leg Piston Rod

-

Forklift Tilting Piston Rod Length 500-7500m

-

Farm Machinery Lifting Piston Rod Length 500-7500mm

Hydraulic rod CK45 Precision Hollow Optical Shaft

1. Material characteristics:

• Chemical composition: CK45 is a medium carbon steel, its chemical composition includes carbon (C) content of 0.42% ~ 0.50%, silicon (Si) content of 0.17% ~ 0.37%, manganese (Mn) content of 0.5% ~ 0.8%, phosphorus (P) content ≤0.035%, sulfur (S) content ≤0.035%. It also contains a small amount of chromium (Cr), molybdenum (Mo), nickel (Ni), copper (Cu) and other elements. This chemical composition makes CK45 steel with high strength and hardness, and at the same time has a certain toughness and plasticity, can meet a variety of machining and use requirements.

• Mechanical properties: With good machining properties, after proper heat treatment, can obtain high hardness and strength. Its mechanical properties such as tensile strength and yield strength are excellent, and it can withstand large loads and stresses. For example, in some mechanical devices that need to bear heavy loads, the CK45 precision hollow optical shaft can work stably to ensure the normal operation of the mechanical system.

2. Structural features:

Hollow structure: The central part of the hollow optical axis is hollow, and this structural design has many advantages. On the one hand, the hollow structure reduces the weight of the optical shaft, and in some equipment or devices with strict requirements for weight, the overall weight load can be reduced, which is easy to install and transport; On the other hand, the hollow structure can provide space for the installation of other components or the passage of cables, for example, in some automation equipment, the sensor cable or hydraulic pipe can be arranged through the inside of the hollow optical shaft, so that the structure of the equipment is more compact and concise.

• High precision size: CK45 precision hollow optical shaft has extremely high dimensional accuracy, including outer diameter size, inner diameter size, straightness, roundness and so on. The dimensional tolerance of the outer diameter and the inner diameter is controlled within a small range, which can ensure the accurate fit with other parts; Good straightness and roundness ensure the smoothness and accuracy of the optical axis when rotating or moving in a straight line, and reduce the vibration and error caused by the shaft’s irregularity or irregularity.

3. Processing technology:

• Processing process: Manufacturing CK45 precision hollow optical shaft requires multiple processing processes, including raw material selection, forging, turning, grinding, heat treatment, etc. Firstly, CK45 steel that meets the requirements is selected as raw material, and the internal structure of steel is improved through forging process to improve its performance. Then the turning process is carried out to remove the excess material and initially form the shape of the optical shaft; Then the grinding process is carried out to improve the surface accuracy and dimensional accuracy of the optical shaft; Finally, heat treatment is performed as needed, such as quenching, tempering, etc., to obtain the required hardness and strength and other properties.

• Surface treatment: In order to improve the surface quality and corrosion resistance of hollow optical shafts, surface treatment is usually carried out. For example, chromium plating, nickel plating and other treatments form a protective film on the surface of the optical shaft, which can not only improve its surface hardness and wear resistance, but also prevent rust and corrosion, and extend the service life of the optical shaft.

4. Application field:

• Mechanical manufacturing: In a variety of mechanical equipment, such as machine tools, injection molding machines, printing presses, etc., CK45 precision hollow optical shaft is often used as a drive shaft, guide shaft, support shaft, etc. Its high precision and high reliability can ensure the accurate operation and stable work of mechanical equipment, and improve the processing accuracy and production efficiency of the equipment.

• Automation equipment: In automated production lines, robots and other automation equipment, hollow optical shaft can provide installation and protection space for various sensors, cables, etc., while its high precision and good motion performance can meet the strict requirements of automation equipment for parts.

• Hydraulic system: In the hydraulic system, CK45 precision hollow optical shaft can be used as the piston rod or cylinder of the hydraulic cylinder to withstand the pressure and friction of the hydraulic oil to ensure the normal operation of the hydraulic system. Its good sealing and wear resistance can prevent the leakage of hydraulic oil, improve the efficiency and reliability of the hydraulic system.

Describe

sign

Introduction of Hydraulic rod CK45 precision hollow optical shaft

As a kind of high quality medium carbon steel material, CK45 hydraulic rod hollow optical shaft has a wide application prospect in machinery manufacturing and rolling industry. Its high hardness and strength, good concentricity and straightness, and the characteristics of reducing wear make it one of the indispensable important materials in these fields.

Steel that meets various standards

Chinese steel: National standard 45# steel

German steel: DIN standard CK45 type

Japanese steel: JIS standard S45C series

American steel grade: AISI Standard 1045

precision hollow optical shaft processing

The workpiece on the sensor and the hollow copper pipe are coiled together, through the high-frequency alternating current, the induced current is formed on the frequency, formed on the surface of the workpiece

so that the surface or local part of the part can be heated rapidly (a few seconds can be heated to 800 to 1000°C, The core is still close to room temperature) after a few seconds, quickly spray (DIP) cooling water (or spray oil cooling) to complete the fire extraction work, and the surface or local hardness requirements.

precision hollow optical shaft specifications

V. Questions and Answers

Q1: Can you customize your product?

We specialize in cylinders, piston rods and cylinders with about 10 years of experience. We have a strong design team, so any ordinary product can be customized.

Q2: How about after-sales service?

We offer a quality guarantee for 12 months after shipment. We also provide long-term technical consulting services.

Q3. What about freight forwarders?

We can accept any type of transportation according to customer’s request.

Hydraulic rod Advantages

1. High-frequency quenching: the piston rod through the high-frequency quenching process, greatly improve its strength and durability. The process works by heating the metal to very high temperatures and then cooling it quickly, causing the metal surface to harden and become more resistant to wear.

2. Tempering: In addition to quenching, the piston rod is also tempering, which involves heating the metal to a specific temperature and then slowly cooling it. The process helps relieve any internal stresses in the metal and improves its toughness and ductility.

3. High quality material: The piston rod is made of high quality steel and is designed to withstand the harsh conditions of industrial use. This steel has been carefully selected for its strength, reliability, resistance to corrosion and other forms of damage.

4. Precision engineering: The piston rod adopts advanced technology and manufacturing process for precision design. This ensures that it operates reliably and consistently, even under the most demanding conditions.

5. Versatility: High frequency quenching and tempering piston rods are suitable for a wide range of industrial applications, including hydraulic and pneumatic systems, mining equipment, construction machinery, etc. It can be used in high and low pressure applications and is designed to withstand heavy loads and vibrations.

By highlighting these key aspects of your product, you can help merchants understand why high-frequency quenching and tempering piston rods are the best choice for their industrial needs. You can also highlight the benefits of using this product, such as increased durability, reliability, and performance, which can help merchants save time and money in the long run.

In addition to highlighting these aspects, it is also important to provide detailed technical specifications and other relevant information about the product. This may include information about the size, weight and other physical characteristics of the piston rod, as well as more technical details about the quenching and tempering processes used in its manufacture.

Finally, it is important to provide excellent customer service and support, including fast and reliable shipping, competitive pricing and responsive customer support. By taking these steps, you can help ensure that your customers are happy and that your business thrives in a competitive global marketplace.

Please feel free to send us your detailed requirements, you will be satisfied with our service.

Contact details are as follows:

Wuxi Shanshen hydraulic machinery Equipment Co., LTD

www.shanshenhydraulic.com

Contact: Sales Manager

Phone:

+ 86-13327929519

+ 86-13382260568

+ 86-13357921819

Email:

admin@shanshenyeya.com

amy@shanshenyeya.com

florence@shanshenyeya.com

stry.