Products

-

Pitch Piston Rod for Forklift Length 500-7500mm

-

Hydraulic piston rod, 50-10000mm length, customizable, used in hydraulic cylinders, forklifts, lifts, etc

-

Multi-cylinder Piston Rod Outer Diameter 4-500mm

-

Pitch Piston Rod for Forklift Outer Diameter 4-500mm

-

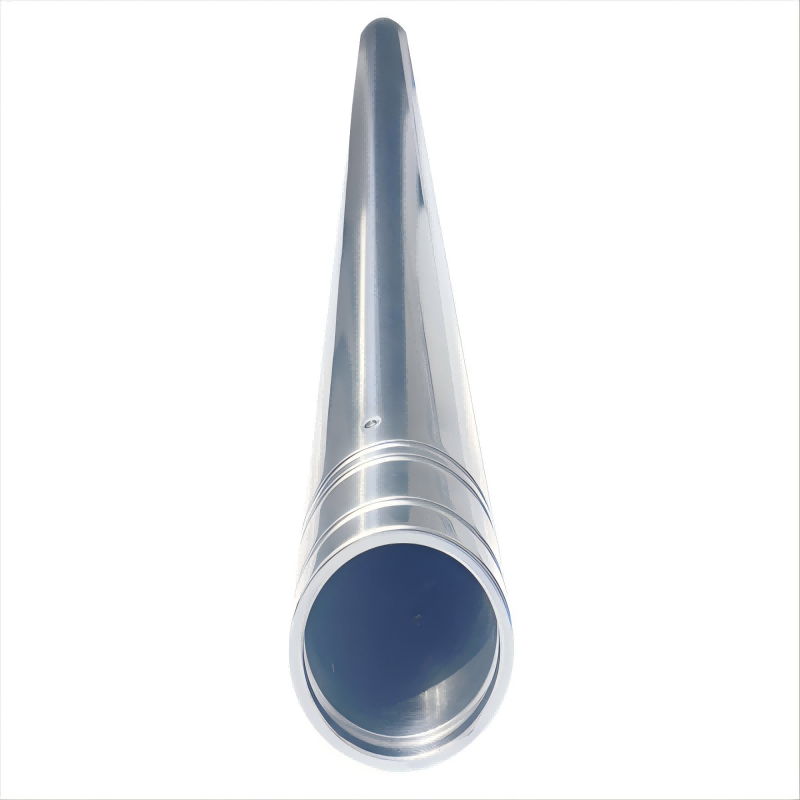

Hollow smooth rod can be customized 50-500mm

-

3T Forklift Steering Piston Rod Outer Diameter 4-500mm

-

Hydraulic rod CK45 Precision Hollow Optical Shaft

-

Automobile hollow rod shaft, diameter 20-500mm, customizable

-

Injection Molding Machine Guide Shaft Outer Diameter 4-500mm

-

Crane Leg Piston Rod Outer Diameter 4-500mm

-

Forklift Tilting Piston Rod

-

Multi-cylinder Piston Rod Length 500-7500mm

-

Forklift Tilting Piston Rod Length 500-7500m

-

Farm Machinery Lifting Piston Rod Outer Diameter 4-500m C45K

-

Threaded hollow shaft,CK45 material, customizable diameter 50-500mm

-

Stainless steel hollow rod, customizable 100-500mm

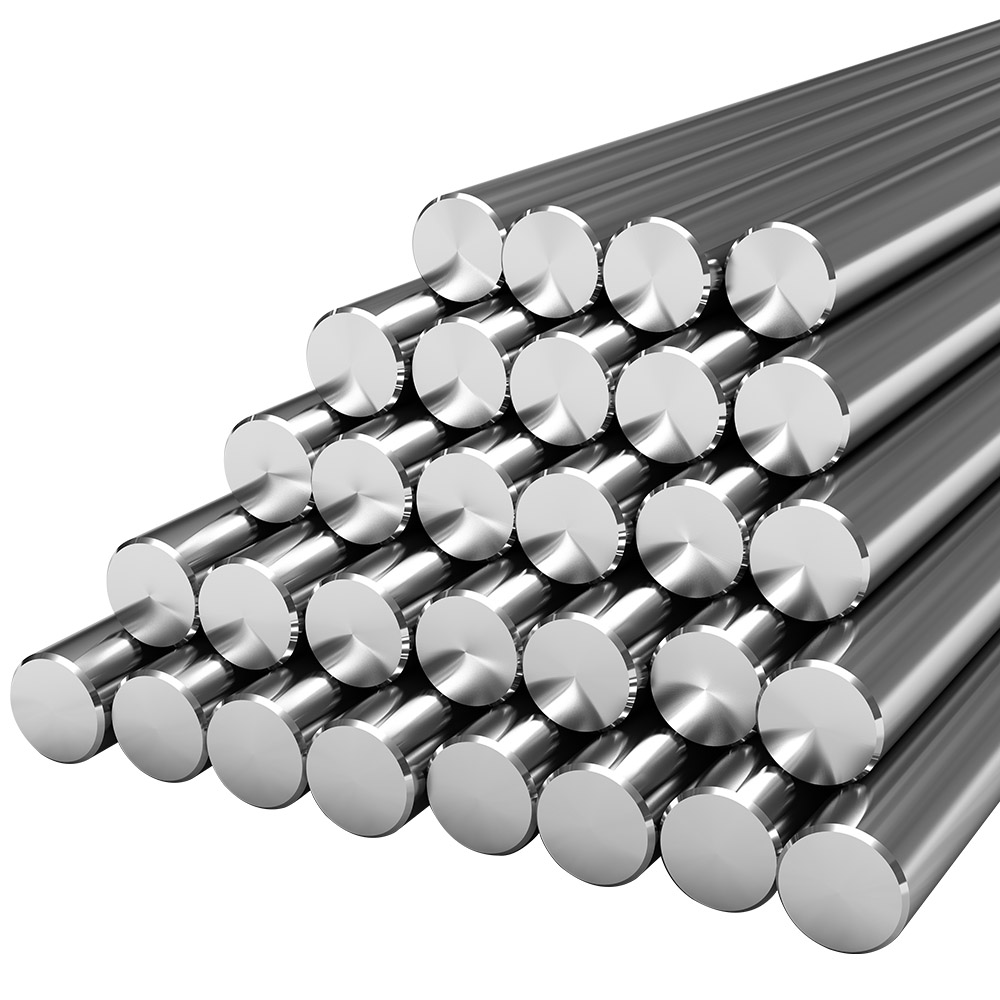

Hydraulic chrome rod Length 30mm-1500mm, customizable, factory direct sales

Wuxi Shanshen Hydraulic Machinery Co., Ltd. mainly produces piston rods, chrome-plated rods, optical shafts, linear shafts, hollow shafts, mechanical guide pillars, etc. We have a whole line of specialized equipment for producing various kinds of shafts. We have a whole line of professional equipment for producing all kinds of shafts, and the shafts we produce have high straightness, good surface finish and uniform hardness. The company specializes in the production of precision slender shafts (piston rods) using precision cold-drawn, precision grinding and high-precision polishing of advanced technology, the technical indicators are in line with and exceed the national standards. Can be directly used for oil cylinders, cylinders, shock absorbers, piston rods, and is widely used in hydraulics and pneumatics, textile printing and dyeing, printing machinery guide rail, die-casting machines, injection molding machine guide rods, piston rods, top rods, and four-column hydraulic presses guide columns; facsimile machines, photocopiers, high-speed mimeographs, printers, and other modern office machinery, such as guides and some of the precision slender shafts.

Describe

sign

- Dimensions, Diameters: Hydraulic chrome rod has a wide range of diameters, which can range from Phi 18 to Phi 250mm according to different application needs.

Length: The length of the piston rod is usually between 15cm and 50cm, but longer lengths can be customized according to specific needs. For example, in some applications, the length of the piston rod may reach 3000mm or 6000mm.

- Hydraulic rod Material: The material selection of piston rod is various, including carbon Steel (such as Steel grade 45#, DIN CK45/JIS 45C), low alloy steel, aluminum alloy, stainless steel and titanium alloy. The choice of these materials depends on factors such as the strength, toughness, wear resistance, heat resistance and corrosion resistance required for the piston rod.

- Mechanical properties: Yield strength: the piston rod needs to have a certain yield strength to ensure that it is not prone to plastic deformation when subjected to external force. Common yield strength requirements are 320Mpa or greater.

Tensile strength: Tensile strength is a measure of a material’s maximum ability to resist tensile damage. The tensile strength of the piston rod is usually required to be ≥580Mpa.

Elongation: The piston rod material needs to have a certain elongation to ensure that a certain degree of plastic deformation can occur without breaking immediately when subjected to tensile forces. Common elongation requirements are ≥15%.

- Surface treatment: The surface treatment of the piston rod is essential to improve its wear resistance and corrosion resistance. Common surface treatment methods include Hard chrome plated and medium and high frequency Induction hardening. Hard chrome plating can improve the hardness and wear resistance of the piston rod surface, while induction hardening at medium and high frequency can improve its internal structure and mechanical properties.

- Tolerance and surface roughness:

Tolerance: The tolerance of the piston rod is usually controlled according to the ISO f7 standard to ensure that its dimensional accuracy meets the requirements of the application.

Surface Roughness: The surface roughness of the piston rod has an important effect on the friction and wear between it and the seal. Common surface roughness requirements are Ra0.2um(max).

- Straightness and quenching hardness:

Straightness: The straightness of the piston rod is an important indicator of its axial deviation. The straightness of the piston rod is usually required to be within 0.2/1000mm.

Induction hardness: For the piston rod that is quenched by medium and high frequency induction, its quenching hardness is usually between 50-55HRC.

- Corrosion resistance:

Salt spray testing (Corrosion resistance) : The corrosion resistance of the piston rod has been assessed through salt spray testing. Min120hours NSS Rating 9 Test acc.To ISO9227 and ISO 10289 Min120hours NSS rating 9 test ACC.To ISO9227 and ISO 10289.

In summary, the technical parameters of the piston rod cover many aspects such as size, material, mechanical properties, surface treatment, tolerance and surface roughness, straightness and quenching hardness, and corrosion resistance.

The selection and determination of these parameters need to be comprehensively considered according to the specific application requirements and working environment.