Products

-

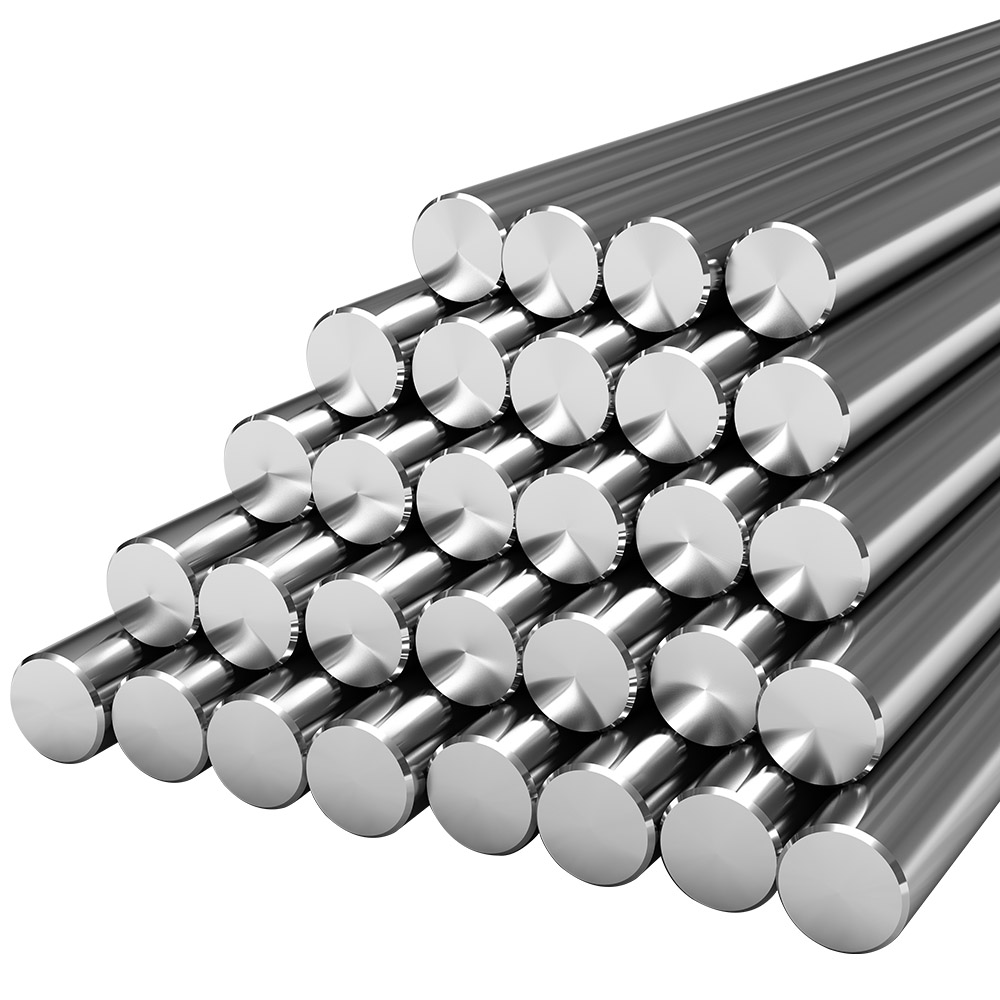

Farm Machinery Lifting Piston Rod Length 500-7500mm

-

Hydraulic piston rod, 50-10000mm length, customizable, used in hydraulic cylinders, forklifts, lifts, etc

-

Hydraulic rod CK45 Precision Hollow Optical Shaft

-

Injection Molding Machine Guide Shaft Length 500-7500mm

-

Threaded hollow shaft,CK45 material, customizable diameter 50-500mm

-

Forklift Tilting Piston Rod

-

Pitch Piston Rod for Forklift Length 500-7500mm

-

Welded Inclined Piston Rod Can Be Customized

-

Multi-cylinder Piston Rod Length 500-7500mm

-

Crane Leg Piston Rod

-

Crane Leg Piston Rod Length 500-7500mm

-

Multi-cylinder Piston Rod Can Be Customized

-

Hollow shaft piston rod

-

Multi-cylinder Piston Rod Outer Diameter 4-500mm

-

Electroplated Rod Can Be Customized

-

Farm Machinery Lifting Piston Rod Outer Diameter 4-500m C45K

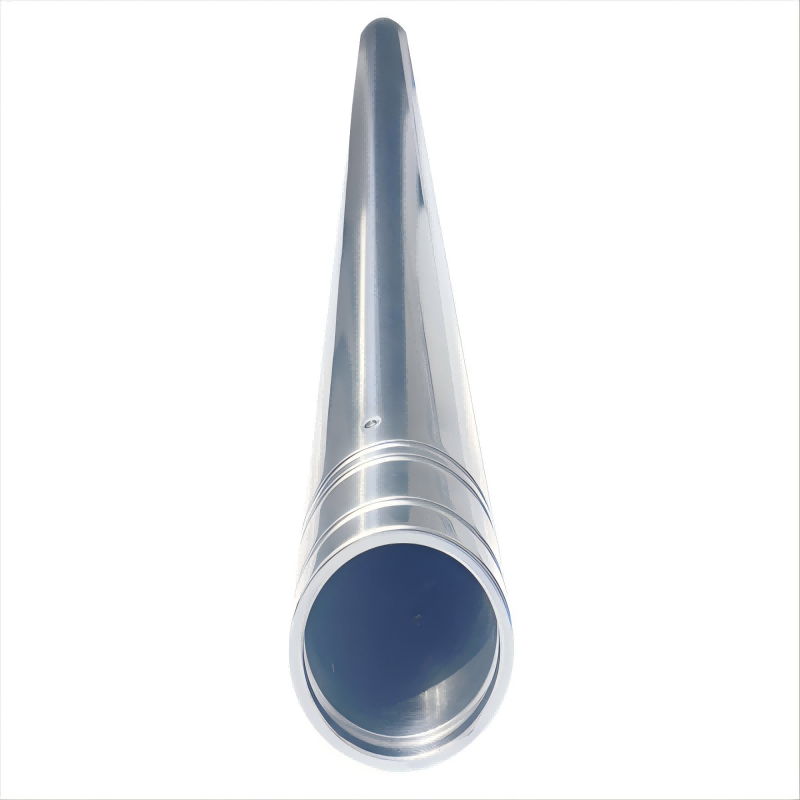

3T forklift steering piston rod

Affect steering performance: The performance of the steering piston rod of the forklift directly affects the steering flexibility, accuracy and stability of the forklift. If the piston rod is worn, deformed or stuck, it will lead to the failure of insensitive steering, inaccurate steering Angle or heavy steering of the forklift, affecting the operation performance and work efficiency of the forklift.

Describe

sign

Product Overview

Forklift steering piston rod is one of the key components of forklift steering system, which has the following characteristics and functions:

1. Structural features:

• Shape: Usually cylindrical, this shape is conducive to linear reciprocating movement in the cylinder, and closely matched with the inner wall of the cylinder to ensure the smoothness and accuracy of the movement.

• Surface treatment: The surface of the piston rod is generally fine processing and treatment, such as grinding, chrome plating, etc. Grinding can ensure the surface accuracy and finish of the piston rod, reduce the friction between the inner wall of the cylinder, the seal ring and other parts; Chrome plating can improve the surface hardness, wear resistance and corrosion resistance of the piston rod, and extend its service life.

• Connection method: one end of the piston rod is connected with the piston, usually fixed by threaded connection, welding, etc., to ensure the fastness and reliability of the connection; The other end is connected with the steering mechanism, and is connected with the steering knuckle arm and other components through the connecting parts such as pins and knuckle bearings to convert the linear movement of the cylinder into the steering movement of the wheel.

2. Principle of action: When the driver turns the steering wheel of the forklift truck, the steering valve in the steering system will control the flow of hydraulic oil, and the hydraulic oil will be imported into one side of the steering cylinder, while the hydraulic oil on the other side will be discharged. Due to the pressure difference of the hydraulic oil, the piston will be pushed, and then drive the piston rod in the cylinder to do linear expansion movement. The movement of the piston rod is transmitted to the steering mechanism of the forklift truck through the connector, so that the wheel deflects, so as to realize the steering of the forklift truck.

3. Importance:

• Affect steering performance: The performance of the steering piston rod of the forklift directly affects the steering flexibility, accuracy and stability of the forklift. If the piston rod is worn, deformed or stuck, it will lead to the failure of insensitive steering, inaccurate steering Angle or heavy steering of the forklift, affecting the operation performance and work efficiency of the forklift.

• Ensure the tightness of the system: the piston rod and the cylinder cylinder need to be sealed by sealing rings and other seals to prevent hydraulic oil leakage. Good piston rod structure and surface quality can ensure a close fit with the seal, improve the sealing performance of the steering cylinder, and ensure the normal operation of the hydraulic system.

In order to ensure the normal operation of the steering piston rod of the forklift truck, it is necessary to maintain and maintain it regularly, including checking the surface wear of the piston rod, cleaning the dirt and impurities on the surface of the piston rod, and regularly replacing the sealing ring.