Products

-

Multi-cylinder Piston Rod Length 500-7500mm

-

Hollow shaft piston rod

-

Crane Leg Piston Rod Outer Diameter 4-500mm

-

Farm Machinery Lifting Piston Rod Outer Diameter 4-500m C45K

-

Farm Machinery Lifting Piston Rod Length 500-7500mm

-

Hydraulic rod

-

Hydraulic rod CK45 Precision Hollow Optical Shaft

-

Welded Inclined Piston Rod Can Be Customized

-

Pitch Piston Rod for Forklift

-

Electroplated Rod Length 500-7500mm

-

Injection Molding Machine Guide Shaft Outer Diameter 4-500mm

-

Electroplated Rod Can Be Customized

-

Hydraulic piston rod, 50-10000mm length, customizable, used in hydraulic cylinders, forklifts, lifts, etc

-

Injection Molding Machine Guide Shaft

-

Hollow smooth rod can be customized 50-500mm

-

Customized 3T Forklift Steering Piston Rod

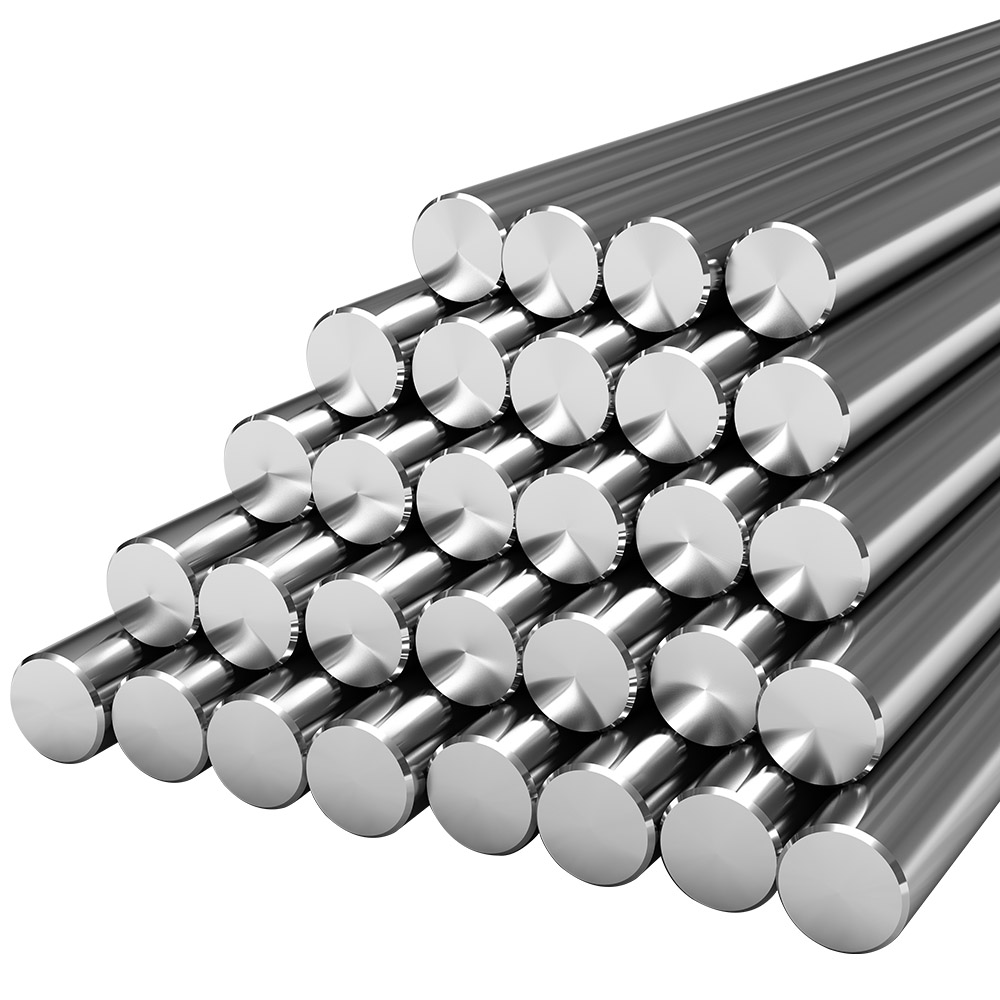

Electroplated Rod Outer Diameter 4-500mm

The Electroplated Rod is a versatile, high-performance component designed for a wide range of industrial applications. Engineered with precision and coated with a durable electroplated finish, these rods offer exceptional durability, corrosion resistance, and superior performance. Whether used in machinery, construction, or manufacturing, the Electroplated Rod delivers reliable and efficient solutions for demanding environments.

Describe

sign

Product Overview

The Electroplated Rod is manufactured using high-quality materials and advanced electroplating techniques. This process involves coating a metal rod with a thin layer of another metal, such as chromium, nickel, or zinc, to enhance its surface properties. The result is a rod that combines the strength and structural integrity of the base metal with the enhanced surface characteristics of the electroplated layer.

Available in various lengths, diameters, and finishes, the Electroplated Rod is designed to meet diverse industrial requirements. Its smooth and shiny surface not only improves aesthetic appeal but also reduces friction and wear, making it ideal for use in applications where precision and longevity are critical.

Product Benefits and Advantages

Durability and Longevity: The electroplated coating provides a robust barrier against corrosion, wear, and environmental factors, significantly extending the rod’s lifespan.

Enhanced Performance: The smooth and hard surface of the electroplated layer reduces friction and wear, leading to improved efficiency and reduced maintenance costs in machinery and equipment.

Versatility: The Electroplated Rod can be used in a wide range of applications, from hydraulic cylinders and pneumatic systems to construction equipment and automotive components.

Aesthetic Appeal: The shiny and smooth finish of the electroplated surface enhances the visual appeal of the rod, making it suitable for applications where appearance matters.

Corrosion Resistance: The electroplated layer acts as a protective shield against rust and corrosion, making the rod suitable for use in harsh and corrosive environments.

Precision Engineering: Manufactured to exact specifications, the Electroplated Rod ensures precise fit and function in all applications, reducing the risk of mechanical failures and downtime.

Product Application

The Electroplated Rod is widely used across various industries due to its robust performance and versatility. Key applications include:

Machinery and Equipment: Used in hydraulic and pneumatic systems, the rod provides reliable performance and longevity, reducing downtime and maintenance costs.

Construction: The Electroplated Rod is essential in construction equipment and structures, offering strength and corrosion resistance for long-lasting performance.

Automotive: In the automotive industry, these rods are used in shock absorbers, steering components, and other critical parts, ensuring smooth operation and durability.

Manufacturing: The rod is utilized in various manufacturing processes, including metalworking, assembly lines, and production machinery, where precision and reliability are paramount.

Aerospace: The high strength and corrosion resistance of the Electroplated Rod make it suitable for aerospace applications, where performance and safety are critical.

Product Unique Selling Point

The unique selling point of the Electroplated Rod lies in its combination of strength, durability, and precision engineering. The advanced electroplating process ensures a hard, smooth, and corrosion-resistant surface that outperforms traditional rods. This makes the Electroplated Rod an ideal choice for demanding applications where reliability and longevity are essential.

Furthermore, the ability to customize the electroplated finish to specific requirements sets this product apart. Whether you need a rod with enhanced hardness, a particular aesthetic finish, or improved corrosion resistance, the Electroplated Rod can be tailored to meet your exact needs.

Product Custom

Customization is a key feature of the Electroplated Rod, allowing it to be tailored to meet specific application requirements. Options for customization include:

Material Selection: Choose from a range of base metals, including steel, stainless steel, and aluminum, to match the strength and weight requirements of your application.

Electroplating Options: Select the type of electroplated coating, such as chromium, nickel, or zinc, based on the desired surface properties and environmental conditions.

Dimensions: The Electroplated Rod can be manufactured in various lengths and diameters to fit precise specifications, ensuring compatibility with your equipment and systems.

Finish: Customize the surface finish to achieve the desired level of smoothness and aesthetic appeal, whether you need a high-gloss finish for visual applications or a matte finish for reduced glare.

Special Coatings: Additional coatings, such as anti-corrosion treatments or hardening layers, can be applied to further enhance the rod’s performance and durability.